Semi Automatic Paint Production Line For Emulsion Paint Production Line in Small and Large Scale Capacity

Other recommendations

Key attributes

Other attributes

mixer type

Agitator

barrel volume (l)

500-10000

material processed

Chemicals, Food, paints&coatings

weight (kg)

5000 KG

product type

Paint

voltage

customized

power (kw)

75 kW

warranty

1 Year

range of spindle speed(r.p.m)

0 - 1450 r.p.m

material

SUS304, SUS304L, Steel for Machine Body

application

Liquid

place of origin

Guangdong, China

brand name

TGM

dimension(l*w*h)

customized

key selling points

High Productivity

machinery test report

Provided

video outgoing-inspection

Provided

core components

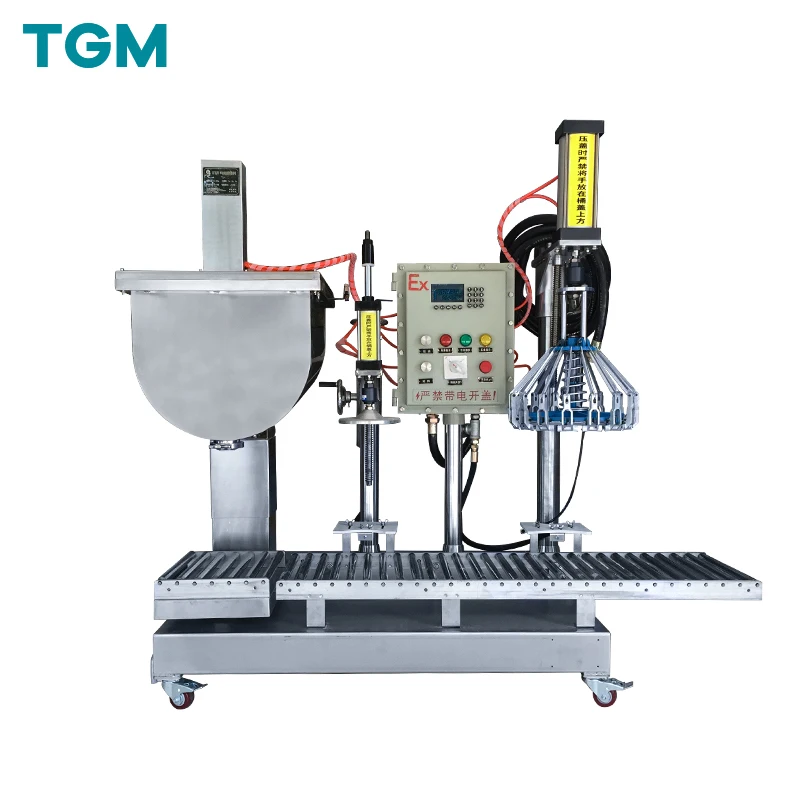

motor, Gear, Pump, Other, Bearing, Engine

Material

Stainless Steel 304 / SUS316L

Product name

paint production line

Application scope

Chemical Cosmetic Food

Advantage

Easy Operation High Efficiency

Motor Brand

made in china

Capacity

200L-50000L

Installation

Provide

Motor

customized

After-sales Service Provided

1 Year

Packaging and delivery

Selling Units:

Single item

Lead time

| Quantity (pieces) | 1 - 100 | 101 - 500 | > 500 |

| Lead time (days) | 20 | 30 | To be negotiated |

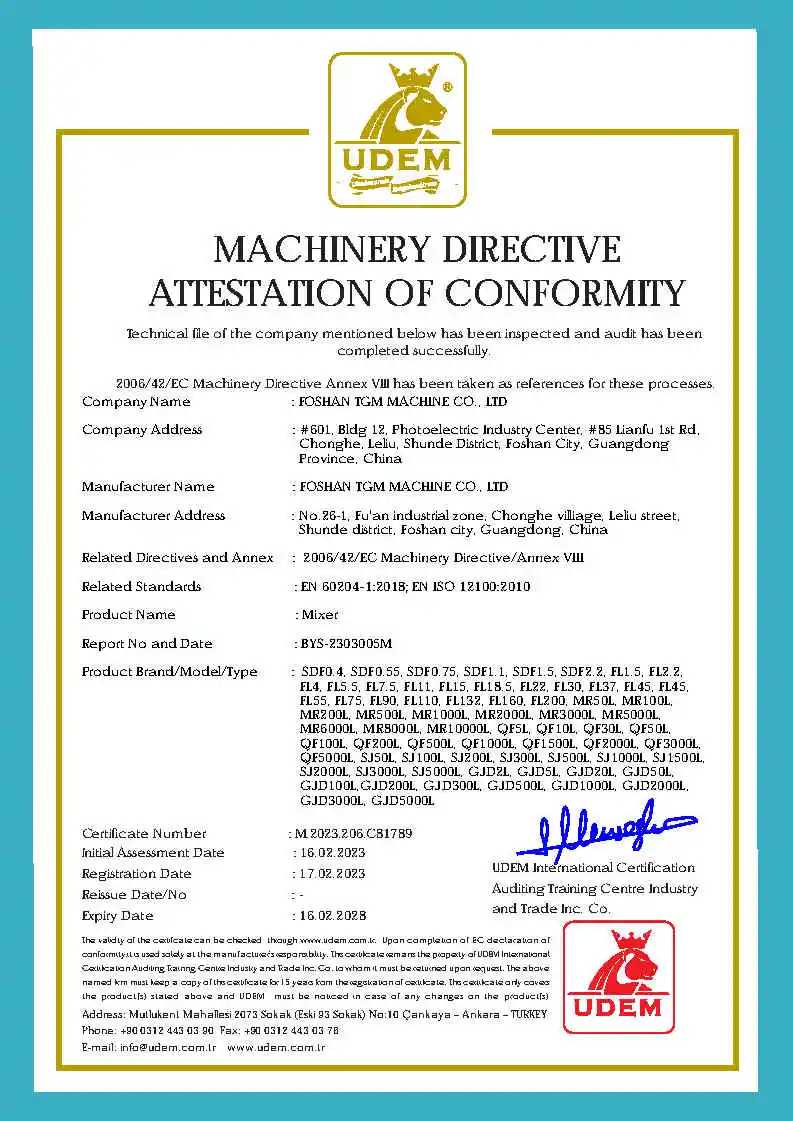

Certifications

Overview

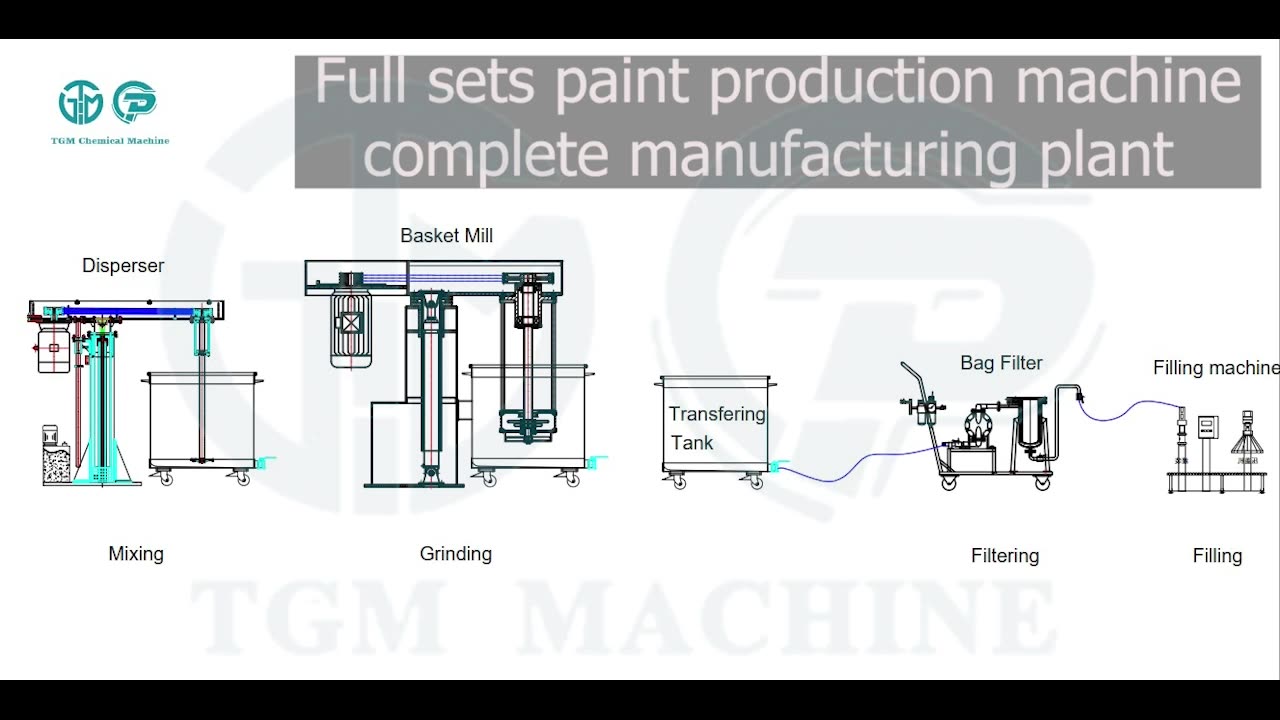

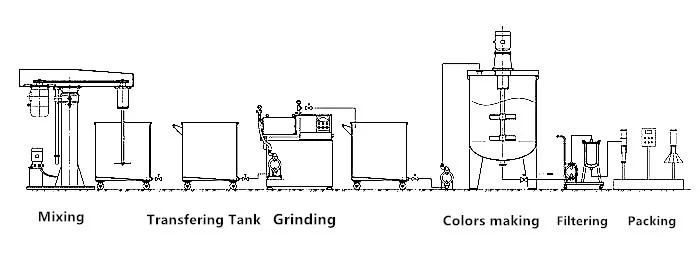

Semi Automatic Paint Production Line For Emulsion Paint Production Line in Small and Large Scale Capacity

* Water Based paints/coatings production line could customize in different production capacity from 200L to 50Tones per day.

* If your paint quality request not very high, the process is Mixing, filtering and packing.

* If your paint quality request high, you should use bead mill, to grind the paints/coatings in small particles. according the

particle sizes requests, there are different quality bead mill for options too.

* Water based paints/ coatings production environment generally no need to be explosion proof, but all our machines are explosion

proof kinds. If you want to save cost you could choose and ask us for non-explosion proof kinds too

* If produce in small capacity, use stand floor mixer and production line will be okay.

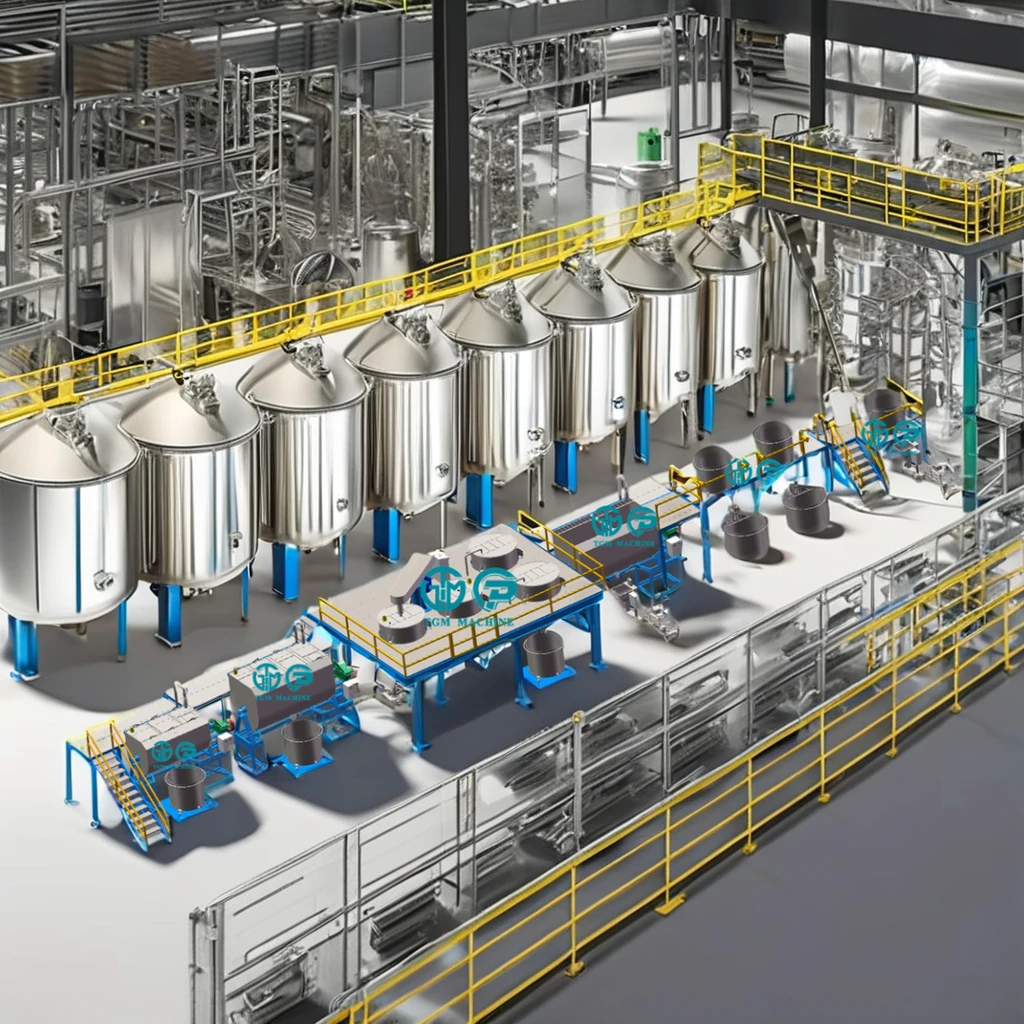

* If large production capacity should use platform mixer.

* If your paint quality request not very high, the process is Mixing, filtering and packing.

* If your paint quality request high, you should use bead mill, to grind the paints/coatings in small particles. according the

particle sizes requests, there are different quality bead mill for options too.

* Water based paints/ coatings production environment generally no need to be explosion proof, but all our machines are explosion

proof kinds. If you want to save cost you could choose and ask us for non-explosion proof kinds too

* If produce in small capacity, use stand floor mixer and production line will be okay.

* If large production capacity should use platform mixer.

Our Advantages:

1. Customized Flexible Production Capacity

2. Fully explosion proof machines provided

3. One stop pants production line machines supply

4. With plant panning service

5. Could Provide installation

6. Easy maintenance machines

7. Plenty of paints and coatings production line experience and projects

TGM Machine is professional in chemical machinery and complete production lines,with 19 years of industry experience.We integrate,design,development, production, sales and trading, maintenance together.We are a leader of this industry. Our company has professional R&D design team, strong technical support, skilled production team, reliable after sales service,flexible customized solutions, to meet your various standards and non standard equipment procurement needs.We committed to providing the complete and professional chemical equipmentsolutions.Our Main business scope: Disperser, Bead Mill, Mixer, Reactor, Filling machine, Bag filter, diaphragm pump, Zirconium bead, 3 roll mill, and other accessories.

Our machines help to make paints,coatings inks pigments, dyes, glues, adhesives,spin finish,wood glue,glue for paper conversion,viscous pastes, concrete Admixtures, PCVC solvent cement,resins ,sealants,silicone sealant, putty, lithiumbattery , electronic slurry&paste,pulps,liquid rubber,pesticide,liquid fertilizer, disinfectant,liquid detergent, lotions, shampoo, body wash liquid soap, hand sanitizer,nail polish,gel,creams,and other chemical and cosmetics products.

1.Are you a factory or a trading company? where is your factory?

-We are a real factory. Our factory is in fu'an industrial zone, leliu street, shunde ditrict, foshan city, guangdong province,China.

2. What are advantages of your factory?

-1)Our factory is a leader manufacture of Chemical machine With 19 years of Industry experience. We have a lot Technology Patents & Product Patents;

2) Our factory has Professional R&D Teams, High Technical Supports, Skilled Production Team, Reliable After Sales Service, Flexible Customized Solutions;

3) Our factory is the leader of this industry, named with high and new technology enterprise;

4) Our factory has plenty of industry experience, we could offer you the complete palnt planning.

3.Who are your factory's clients? Could you list some of them?

-AKZONOBEL, JUNTON, PPG, NIPPON, DABAO, BURGER, MAYDOS, RAINBOW, HITECH COATING, CHINA PAINT, CHANGJIANG COATING, TOA, LYNWON PIGMENT, PEONY INKS, TL INKS, ZR INKS, SAKATA INKS, KINGSWOO INKS, DIC INKS, ANLI, ACHILLES, REPOW GROUP, SHINETSU ADHESIVES, JUSHI, XINGLONG PESTICIDES, BYD, CATL...

4.Which countries your machine sold to?

-American Market: America, Canada, Mexico, Brazil; -European Market: UK, Germany, Netherlands, Bulgaria, Italy, Russia; -African Market: South Africa, Algeria, Zambia, Cameroon, Ethiopia, Uganda, Madagascar; -Asian Market: Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Bangladesh, India, Pakistan, Lebanon, Iran, Iraq, Egypt, Qatar, Turkey, Saudi Arabia, UAE;

5.Could your factory provide formula and raw materials service?

-.Basically we are machinery suppliers, not products chemist. For some paint&coatings, silicone sealant, textile printing adhesives or pesticide we could help you find chemist and raw materials from our cooperative clients. Other products we are not sure. But if you need our help, we will try our best to dicuss with our serviced cleints and see if they would like sell to you formula or not.

6.Do you have agent in our country?

-1.No, we ship directly from China to you. our machines generally ship without dismounting. You generally only need to connect electricity, you could use directly. If need installation, we provide detailed installation instruction for full line or we send engineers to help you with paying.

7.What's the payment method?

-We accept T/T and L/C payment.

- Tel:

-

Email:

INQUIRY

Certifications

SUBSCRIBE

INQUIRY