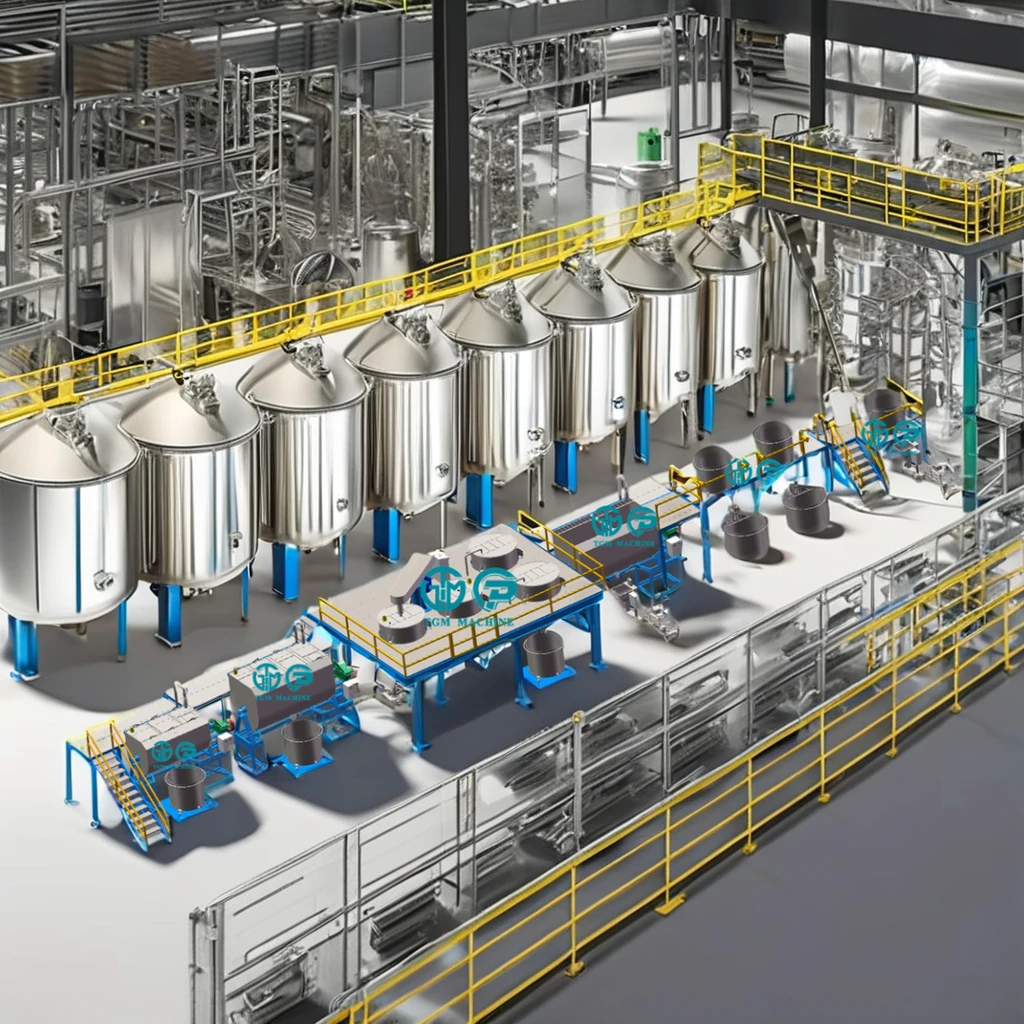

Water-Based Latex Paint Manufacturing Equipment SUS304 Material Homogenizer Platform Liquid Dispersion Chemical Production Line

Other recommendations

Customization

Customized packaging

Min. order: 5

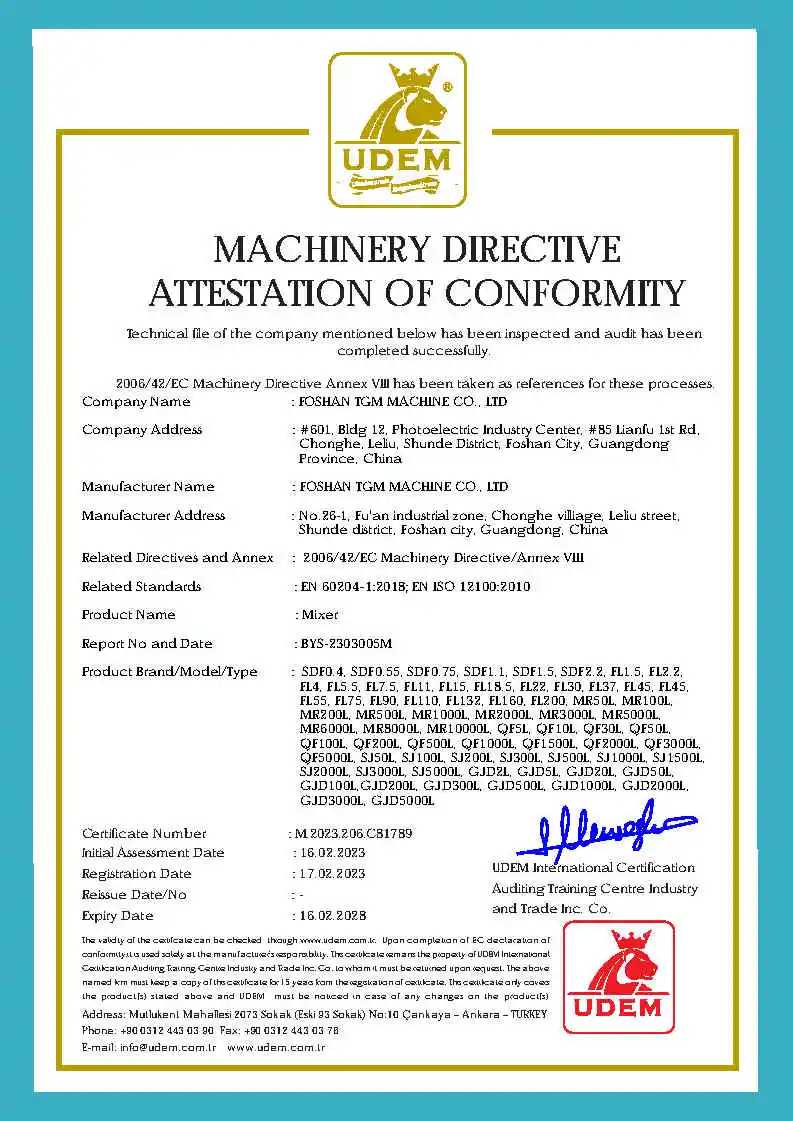

Certifications

Overview

| item | value |

| Barrel Volume (L) | 3000 L |

| Max. Loading Volume (L) | 3000L |

| Mixer Type | Agitator |

| Material Processed | Chemicals |

| Weight (KG) | 3500KG |

| Condition | New |

| Place of Origin | China |

| Power (kW) | 75kW |

| Warranty | 1 Year |

| Key Selling Points | High Productivity |

| Applicable Industries | Manufacturing Plant, paint manufacturing plant, coating factory, ink factory, paint factory |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 YEAR |

| Core Components | Bearing, MOTOR |

| Range of Spindle Speed(r.p.m) | 0r.p.m - 1500r.p.m |

| Max. Loading Capacity | 10000 |

| Material | SUS304 |

| Product Type | Other |

| Application | Liquid with Suspended Solids |

| Additional Capabilities | Milling |

| Brand Name | TGM |

| Voltage | 3Phase 380V 50HZ |

| Dimension(L*W*H) | 3000*2000*2000mm |

1.Customizable Production

The Emulsion Paint Production Line is designed as an industrial blender mixer machine, adaptable to a wide range of needs in the chemical production line, with options to choose from various capacities, ranging from 500L to 10000L. It offers flexibility, making it suitable for diverse applications in the paint, ink, pigment, and resin manufacturing industry.

2.High Efficency and Accuracy

With a 1500rpm spindle speed range and a maximum loading capacity of 10000L, the machine efficiently discharges the materials, ensuring smooth production flow and enhancing product consistency. Its high-speed shear mixer and agitator features contribute to the overall efficiency, meeting the fast-paced demands of the manufacturing plant.

3.High Durability and Reliability

Manufactured from stainless steel 304, the Emulsion Paint Production Line is built to withstand corrosion and deterioration. This ensures long-lasting performance, with a one-year warranty on the core components of the machine. The sturdy SUS304 materials used in its construction ensure its durability and reliability in various chemical factory environments.

4.Improved Mixing Performance

Equipped with a high-speed motor capable of 75kW and 380V/50HZ voltage, the machine provides efficient and powerful mixing performances. The mixer's core components, including bearings and motors, are designed for optimal performance and minimized maintenance.

5.Advanced Safety Measures

The Emulsion Paint Production Line complies with international safety standards, featuring protective enclosures and safety interlocks to safeguard users against potential hazards. These measures ensure a safe working environment, making the machine suitable for use in various manufacturing plants, including paint and ink factories.

Established for 19 years, TGM a professional standing within the chemical machinery and production line industry. Our comprehensive, integrated service encompasses a diverse range of activities including design, development, manufacturing, sales, trading, and after-sales support. In recognition of our expertise, we act as a leading figure within the sector.

At TGM, we pride ourselves on our proficient R&D design team, robust technical infrastructure, and a highly skilled production crew. We further bolster our services with efficient after-sales support and innumerable customizable solutions. Our commitment is to provide customized solutions for your specific equipment requirements and catering to the procurement of varied industry standards.

Our primary areas of business include machinery for dispersers, bead mills, mixers, reactors, filling machines, bag filters, diaphragm pumps, zirconium beads, 3-roll mills, and other accessories. These machines are tailored to meet demanding industrial processes and applications involving paints, coatings, inks, pigments, dyes, glues, adhesives, sealants, resins, and silicone sealants.

TGM is steadfast in its commitment to the creation of a comprehensive and professional solution in the chemical and cosmetics industry. Our expertise extends to manufacturing products like lithium battery, electronic slurries and pastes, pulps, liquid rubber, pesticide, liquid fertilizer, disinfectants, liquid detergent, lotions, shampoos, body wash, liquid soap, hand sanitizers, nail polishes, gels, and creams, amongst others. We strive for continuous innovation and dedication to quality, aiming to be your trusted partner in the field of chemical and cosmetic equipment solutions.

1. who are we?

We are based in Guangdong, China, start from 2012,sell to Domestic Market(71.00%),Africa(8.00%),Mid East(6.00%),Southeast Asia(5.00%),North America(3.00%),Western Europe(2.00%),South Asia(1.00%),South America(1.00%),Oceania(1.00%),Southern Europe(1.00%),Eastern Europe(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Disperser, Mixer, Bead Mill, Bag Filter, Filling Machine

4. why should you buy from us not from other suppliers?

TGM Machine is a chemical equipment manufacturer. We are a real factory to provide you not only individual machine, but also great planning for your plant, tech supports, good after sales, and full production line solution.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU;

Accepted Payment Currency: USD,EUR,CAD,AUD,HKD,GBP,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken: English,Chinese,French

- Tel:

-

Email:

Certifications

SUBSCRIBE

INQUIRY