Wholesales Vacuum High Speed Dispersion Mixer Disperser For Dyes Pigment Ink

Other recommendations

Customization

Customized packaging

Min. order: 1

Customized logo

Min. order: 1

Graphic customization

Min. order: 1

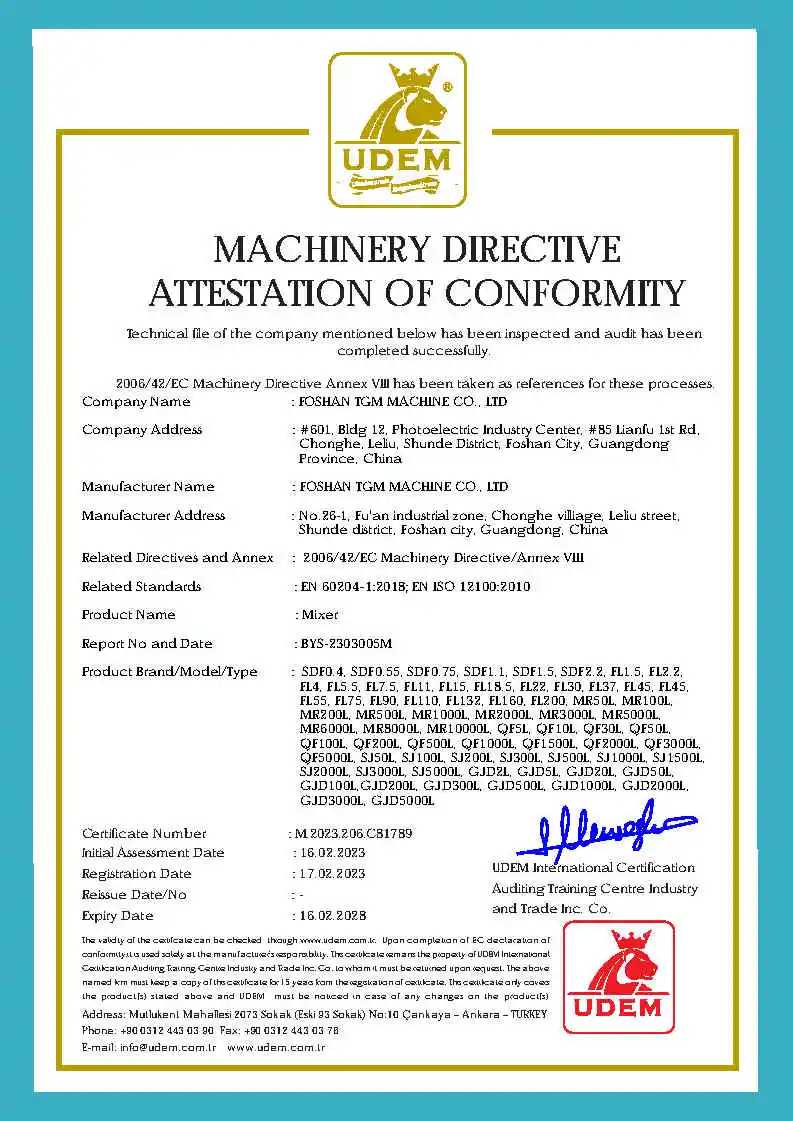

Certifications

Overview

TGM Factory Direct Sales Hydraulic High Speed disperser for mixing paint and coatings Specifications:

pattern and desired consistency in your mixing vessel. The right amount of dispersion will ultimately depend upon your mixing

vessel size and the components you wish to mix. Your vessel can range in size from a beaker to stainless steel tank. Generally

speaking, the high speed disperser is designed for performing liquid mixing operations in which it is necessary to reduce the pieces of one element or break apart a mass or group of particles.

Projects showcase:

Related products:

TGM Factory:

TGM Chemical Machine Co., Ltd is a group enterprise. We are a leader in the field of chemical machine industry, with 18 years of industry experience.

We integrate, design, development, production, sales and training together. We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions,to meet your various standards and non standard equipment procurement needs. We committed to providing the complete and professional chemical equipment solutions.

Our products scope: Disperser, Bead Mill, Basket Mill, Mixer, emulsifier, Mixing kettles, Reactor, Filling machine, Bag filter, Pumps, Zirconium Bead, 3 roll mill, and other accessories.

Our machines help you to make ideal products: paints, coatings, inks, pigments, dyes, thinner, hardener, emulsions, varnish, spin finish, putty, glues, adhesives, viscous pastes, concrete Admixtures,

PCVC solvent cement, liquid resins, sealants, silicone sealant, lithium battery, electronic slurry&paste, pulps, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, liquid detergent, gel,

lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on.

We could offer individual machine or full production lines for your plants.

Who are your factory's clients? Could you list some of them?

AKZONOBEL, JUNTON, PPG, NIPPON, DABAO, BURGER, MAYDOS, RAINBOW, HITECH COATING, CHINA PAINT, CHANGJIANG COATING, TOA, LYNWON PIGMENT,

PEONY INKS, TL INKS, ZR INKS, SAKATA INKS, KINGSWOO INKS, DIC INKS, ANLI, ACHILLES, REPOW GROUP, SHINETSU ADHESIVES, JUSHI, XINGLONG PESTICIDES...

Certificate:

Packing and shipping:

Certifications

SUBSCRIBE

INQUIRY